How were knife blades forged before electricity?

These days we seem to be marvelling at technology... while at the same time advocating energy conservation.

Some may have forgotten, but yes, blacksmiths made knives long before the advent of electricity!

Today we pay tribute to those who had the genius and know-how to create tools as precious and durable as knives.

Let's take a journey through time together to understand how these ancestral objects were made, from the first "cutlers" to the techniques of today.

What materials were knives made of before the electric current?

The first knives made of stone, flint or obsidian date from around 25,000 years ago, archaeologists have also

discovered tools with sharp flint edges that are 2.6 million years old. This is even older than our species, Homo sapiens! Obviously, our bipedal ancestors understood that life was much easier with knives than without. The history of knives therefore began very early in the development of our human civilisation.

These "knives" were not very refined, as they were usually made by breaking stones to create a sharp blade-like edge. Similar methods were used to create arrowheads and spearheads. These tools were quite primitive but enabled our hominid predecessors to hunt, fish, defend themselves against animals, harvest and process food.

Knives and blades became much more refined after the appearance of Homo sapiens. For the vast majority of our human history, only stone tools and implements have been used. The design of sharp stone tools was perfected at the end of the Lithic period, and various techniques were used to make these 'knives' in the Neolithic period.

Another way of making knife blades before the advent of electricity.

The earliest form of forging is thought to have begun in Mesopotamia, around 4500 B.C. Ancient metalworkers worked mainly with bronze, which was soft and could be melted and formed in moulds. Centuries of bronze working followed, not only in Mesopotamia, but also in Greece, Egypt and other parts of ancient Europe and Africa.

Remember your history lessons... The Iron Age is the period when the use of iron became widespread in Europe, Asia and parts of Africa. As the adoption of iron did not occur at the same time in all parts of the world, there is not really one Iron Age, but rather several across different regions.

"The oldest iron objects in the world... begin to appear around 3000 BC," says Nathaniel Erb-Satullo, senior lecturer in archaeological sciences at the Forensic Science Institute in Cranfield, UK. But "this is well before what we call the Iron Age."

With the new interest in metals, people began to experiment with different ways of shaping them, melting them and identifying the different types of metals. Some metals needed more heat to melt. Some were harder than others. Eventually, by accident or by intentional experimentation, someone discovered that adding tin to copper made a harder metal. The combination of two metals into a new substance is called an alloy. With a proportion of 90% copper and 10% tin, a whole new era was born: the Bronze Age.

Iron swords and daggers did not begin with the Iron Age. King Tutankhamun was buried with an iron dagger probably made from a meteorite in the 14th century BC, long before scholars placed the beginning of the Iron Age. The main innovation of Iron Age weapons was not that they used iron, but that they eventually used steel produced by new metallurgical techniques.

Early iron swords were not necessarily better or harder than those made of bronze, but innovations such as tempering made it possible to make solid steel swords that became more common over time. One of the most famous steel swords of the Iron Age is the Vered Jericho, which dates from the 7th century BC in ancient Israel.

Even as iron and steel became more widespread, Iron Age peoples continued to make bronze weapons and tools.

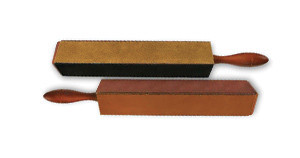

It should be noted that metal blades were not as sharp as stone ones and did not retain their edge as long. This led to the use of sharpening stones to maintain the function of these new tools.

With the industrial revolution, technological development allowed modern manufacturers to produce stronger, sharper and more durable blades through heat treatment and tempering techniques.

Techniques and tools used

Ancient knifemakers knew different methods and tools needed to build knives, and funnily enough, these tools are still used:

Forging: Forging involves heating the metal to a temperature where it can be handled easily. Once the metal has cooled down, further work is done on it to obtain a specific shape.

Grinding wheel: Grinding wheels are made up of abrasive stones mounted on a shaft that rotates at high speed to sharpen the blade and give it its final shape.

Sharpening: Craftsmen use special tools to sharpen blades and give them a sharper edge. Sharpening stones are still in use today, so they are very effective!

Historical references...

antique forgeHandmade knife blades have been produced for many years, in different models that have varied according to the region.

Here are some historical references:

Medieval knife blades: This type of blade is characterised by its triangular length and width. They were mainly custom-made for use as a tool and weapon, and could be found in all social strata.

Viking knife blades: Used during the Middle Ages and produced mainly in Scandinavia, the Seax knife, also known as "Historic Viking Scramasaxe" or "Sax", has a blade shape with the edge always facing upwards, not downwards like our usual knife.

Asian knife blades:"Knife" was originally written as "Cultellus". The "庖" in this 庖 子 refers to a cook. The earliest Sakai cutlery techniques date back to the 5th century! In the 16th century, Sakai craftsmen expanded their production range to blades for various purposes (swords and knives).

Ancient materials used for knife blades.

Before metals were available for making blades, they were cut from stones or bone.

Over the ages, knife makers have found various ways to improve and refine their manufacturing technique to make a stronger, more durable blade.

Some of the ancient materials used for blades include:

Stone: Stone, flint or obsidian most often in the form of rough flakes, dated to around 25,000 years ago.

Bone: Natural bones such as those from deer or bison were often used to create a primitive blade.

Wood: Men used solid wood such as oak or walnut to make handles. Now there are many different types of wood used to make handles.

Bronze: From the Bronze Age onwards, knives were made of metal, almost immediately of iron, as bronze was not hard enough.

Metal: the Romans made the first steel blades, as they also made the first folding knives from the 1st century onwards.

Damascus: it seems that damascus originated from the soaking of leather tools in tanning baths. These baths, which were based on acidic elements, must have revealed the patterns on the tools with heterogeneous metals.

Did you know? It was not until 1921 that the first stainless steel knives were produced in the USA.

Difficulties encountered in manufacturing without electricity.

The demanding and complicated process involved in making blades before electricity and the use of modern tools was an additional challenge for the craftsmen of the past:

Lack of precision: When forging metal by hand, it was not possible to achieve a uniform surface or even an exact shape.

Manufacturing time: Blade making requires several hours depending on the complexity of the knife.

Cost of materials: The raw materials used to make the blades were expensive to buy and in terms of effort, which is why the most efficient knives were reserved for the wealthy.

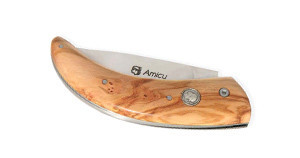

Advantages of handmade blades... today!

Although time-consuming and expensive, handmade blades still have several advantages:

Superior quality: Handmade knives can be stronger and more durable than industrially made ones because they are made of better quality materials.

Durability: Blades last for years without weakening or wear.

Unique design: Each blade produced is different from the others and reflects the skill, talent and artistry of the knife maker.

As you can see, knife making goes back to ancient times. The ancient version of knife making did not rely on the use of advanced tools, but rather on a combination of rudimentary hand tools and a fair amount of ingenuity.

Although complex and expensive, this method allowed ancient craftsmen to produce strong, durable blades that have stood the test of time!