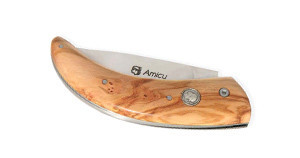

Knife assembly

Our knives are made in the town of Thiers, in the Auvergne region. The cutlery tradition of Le Thiers is a guarantee of high-quality steel. Altough the knife manufacturing process has evolved with time, laguiole knives remain handcrafted knives handcrafted knives. Our knives are adjusted by hand according to ancestral methods. They have a lifetime warranty

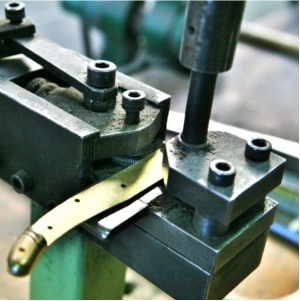

Illustrating the knife assembly process

Illustrating the knife assembly process

After a rigorous quality control of parts, the cutler begins the hand assembly and shaping of the knife.

- He prepares the wooden board for the handle

- He makes a first assembly

- He disassembles it to adjust and polish the blades and springs

- He makes the final assembly and finishing polishing ang sharpening

Our knives are made in Thiers, in Auvergne. Thiers’ cutlery-making tradition dates back to the 15th century, when the pure water flowing down from the Massif Central mountains gave steel tempering an exceptional character. Cutlery-making has become more modern of course, but laguiole knives making remains a craft.

Knife assembly is a key step in the laguiole manufacturing process. Our cutlery-makers take the greatest care when performing it since it is when you knife acquires its solidity, impeccable finish and perfect locking characteristics.

Our knives are adjusted by hand according to age-old methods. We guarantee their perfect finish, the quality of each of the elements they are made of as well as the seamless fit of all the components together. How serious are we about this ? Our laguioles come with a lifetime guarantee.

Preparing the handle

Preparing of wooden boards is the first operation to prepare the handle

Step 1

The plates are used as template cutting wood platelets to the right size

Step 2

The wooden boards are adjusted to the shape of the plates

Step 3

Wooden boards are pre-drilled for easy mounting of the knife

First assembly

First assembly of the knife

Step 2

The curvature of the handle shaped by the use of an abrasive belt

Disassembly

Disassembly of knife handle

Step 1

The handle is disassembled and the plates are polished

Step 2

A roulette wheel adorns.The upper part of the plates

Final assembly

Final assembly of the knife

All parts are ready, now they have to be assembled

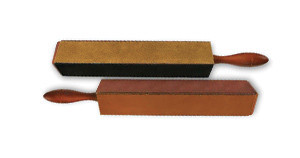

Finishing touches

Bringing the finishing touches to the knife

Step 1

One last go on the abrasive belt, to give the knife handle its gently curved shape

Step 2

Final polishing of blade and handle

Step 3

Last sharpening for the blade